Home > News Archive > Applied Minerals and OPF Enterprises, LLC to Develop Ceramic Proppants Utilizing the Dragon Mine Clay Resource

- October 28, 2013

- Applied Minerals and OPF Enterprises, LLC to Develop Ceramic Proppants Utilizing the Dragon Mine Clay Resource

- Development efforts focused on the ceramic proppant market for hydraulic fracturing

- Proppant formulations utilize unique characteristics of the Dragon Mine’s alumina-rich clay resource

- Proppants developed to-date meet or exceed certain performance metrics of market-leading products

- Initial focus on supplying shale formations that are heavy users of ceramic proppants and are in close proximity to the Dragon Mine

NEW YORK -- October 28, 2013 -- Applied Minerals, Inc. (the “Company”, “Applied Minerals”) (OTCQB & OTCBB: AMNL), a leading global producer of halloysite clay and high-grade iron oxide, today announced that it has entered into a development agreement with OPF Enterprises, LLC (“OPF”), a leading ceramic consulting firm that focuses on ceramic materials and process development, to formulate a range of ceramic-based proppants to market to oil and gas drillers in shale formations in close proximity to the Company’s Utah-based Dragon Mine.

Preliminary development work indicates that the presence of both halloysite and other clay minerals found in areas of the Dragon Mine resource produce ceramic proppants with attractive crush strength, permeability and specific gravity characteristics that meet or exceed certain performance metrics of several competing ceramic-based products.

Formulations will primarily utilize alumina-rich clay found both in the mine’s Western Area resource and five surface piles, which possess chemistries very similar to the ceramic proppants currently on the market. The Company’s higher-grade clay resource, located in the Dragon Pit area of the mine, will continue to be used to develop higher value applications such as polymer composites, flame retardants, environmental remediation, controlled release carriers and catalysts.

Applied Minerals is advantageously positioned to capitalize on the attractive growth prospects of the proppant market due to the proximity of its Dragon Mine to the Bakken Shale, a user of approximately $1.0 billion of ceramic proppants per year, the largest in North America. The Bakken region is served primarily by ceramic producers located in Arkansas, Alabama, Georgia and China, against all of which the Dragon Mine has a meaningful logistical advantage.

Applied Minerals and OPF will continue to work on optimizing a range of ceramic-based proppants and identifying a strategic partner with whom to commercialize a ceramic proppant manufacturing operation.

Development of Ceramic Proppants

Proppants are spherical beads designed to keep an induced hydraulic fracture open during the fracturing process (also known as “fracking”) used to access deep oil and gas resources. Ceramic-based proppants have been developed to meet the higher performance requirements needed by unconventional, multi-stage horizontal drilling to hold open shale fractures at increasingly lower depths where significant oil and gas resources exist.

Deep shale drillers utilizing hydraulic fracturing are continually striving to identify ceramic proppants that are lighter, stronger and exhibit superior conductivity and permeability. Increased lightness is needed to ensure the material sufficiently fills the fractures created in the shale, reducing the volume of water and chemicals required; improved strength is required to keep fractures open under the greater pressures experienced at deeper drilling depths; and enhanced porosity is desired to increase the flow of the oil and gas liquids freed through the fracturing of the shale.

As mentioned earlier, development work indicates that the presence of halloysite and its unique tubular morphology within the clay mixtures found in both the Dragon Mine’s Western Area and the five surface piles can be used to develop a range of ceramic proppants that provides the desired specific gravity, strength, conductivity and permeability needed in demanding driller operations such as the Bakken Shale. The range of proppant products will be based on varying ceramic blends drawn primarily from these resources. Different mesh sizes and strengths will address a number of performance and price points.

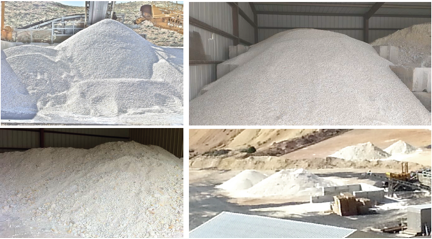

Fired ceramic proppant using Dragon Mine clay

Ceramic Proppant Market

Drillers in the Bakken formation are some of the heaviest users of ceramic proppants due to the high pressures and temperatures encountered at drilling depths from 8,000 to over 12,000 ft. According to The Freedonia Group, Inc., approximately 5.3 billion lbs. of ceramic proppant were consumed in North America in 2012. Assuming a current average selling price of $0.30 per lb., the value of the market in 2012 was approximately $1.6 billion. The Freedonia Group, Inc. expects North American volume consumption of ceramic proppants to grow at a compounded annual rate of 8.8% from 2012 through 2017.

As seen on the map below, the Dragon Mine’s location in southwestern Utah provides a logistical advantage with respect to supplying both the Bakken formation and the Niobrara shale basin, two heavy users of ceramic-based proppants. With the majority of ceramic proppant suppliers to the Bakken and Niobrara formations located in Arkansas, Alabama, Georgia and China, the Dragon Mine has a meaningful advantage with respect to cost of delivery.

Proximity of Dragon Mine to Bakken and Niobrara Shale

Other Markets

In addition to ceramic proppant applications, OPF has agreed to assist in furthering the development of the Company’s Dragon Mine clay for use in traditional application areas such as technical ceramics, catalysts and supports, and porcelain, which would benefit from the unique structure, high plasticity, and high alumina to silica ratios of the Company’s clay resource.

The Dragon Mine

Since January 2009, under the direction of consulting geologist Ian Wilson, PhD, the Company has invested over $7 million in the geological characterization, quantification and development of the Dragon Mine’s clay resource. The property contains an underground halloysite resource, an underground kaolinite resource, and five clay-bearing surface piles located on the property. Typically, only deposits with high levels of alumina bearing clays (a minimum of ~25% alumina content) can be used to make ceramic-based proppants that meet the demanding requirements of deep drillers.

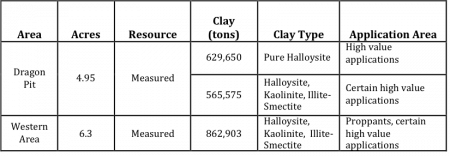

The Company expects the Western Area and the five surface piles of the Dragon Mine to be the primary sources of clay from which proppant material will be formulated. The Western Area of the Dragon Mine includes 862,000 tons of clay consisting primarily of high alumina kaolinite with a presence of halloysite, gibbsite, alunite, as well as hematite, an effective fluxing agent utilized in the production of proppants. The property’s five surface piles contain 4.5 million gross tons of clay and iron-bearing material that, upon refining, is believed to be suitable for ceramic proppant production.

Below is a summary of the Company’s underground and surface pile clay resources prepared independently by consulting geologist Ian Wilson, PhD:

Underground Resource

Surface Piles

A full copy of the updated resource statement can be viewed at Applied Minerals 2013 Resource Statementor by going to the "Investor Information" section of the Company's website.

Operations at the Dragon Mine

Underground resource at the Dragon Mine

Aerial Picture of the Dragon Mine, Tintinc District, Utah

Characterization

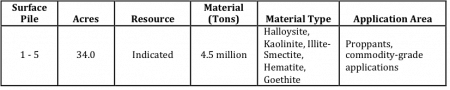

Through the services of Macaulay Scientific Consulting, Ltd. (Scotland, UK), significant resources have also been invested in developing an understanding of the mineralogy of the property’s clay resource. The property contains an underground resource of primarily kaolinite (Western Area), an underground resource of primarily halloysite (Dragon Pit area), and five surface piles bearing an array of clay minerals. Kaolinite is a very common layered silicate mineral used in a range of industrial applications. Halloysite, while chemically identical to kaolinite, possesses a tubular rather than platy morphology that delivers advanced functionality to a number of commercial applications including ceramic-based proppants.

SEM of Dragonite Halloysite Tubes SEM image of Kaolinite platelets

The Company is in the final stages of constructing a multi-million dollar processing plant. The plant will utilize an advanced clay processing technology with a production capacity of up to approximately 45,000 tons per annum of saleable clay material. Clay material processed by the plant would be used as input material for the manufacturing of ceramic proppants. The Company believes the expansion of the plant’s capacity would require minimal capital investment. This advanced processing capability will enable Applied Minerals to tailor the physical properties of its clay mineral. The property has all necessary permits and environmental clearances.

Processing plant under construction at the Dragon Mine

Geology of Resource

The Dragon Mine property (Juab County, Utah) is located approximately two miles southwest of Eureka, UT in the Tintic Mining District and can be accessed via state highway and county road. The Union Pacific Railroad has a spur approximately two miles from the property. The property covers approximately 266 acres, includes 38 patented and six unpatented claims. Currently there are two underground portals with active workings. The five surface piles are the result of previous miningoperations that took place between 1949 and 1976. The piles contain varying amounts of different clays and iron oxides. Applied Minerals has full ownership of the Dragon Mine and operates year round under a large mine permit.

Geological Setting

Geologically the Dragon Mine is varied with Palaeozoic limestone being intruded by the Tertiary igneous Silver City monzonite porphyry and iron oxide. The mineralization is fault controlled and the clay mineralogy is often dependent on the host rock. In the pit area of the mine, where there is a large body of iron oxide, the clay is predominantly halloysite (100% in many places) with the potash feldspar in monzonite being altered to halloysite, kaolinite and illite‐smectite. The iron oxide is a mixture of ultra-pure goethite and hematite.

Stockpiles of clay at the Dragon Mine

Operations at the Dragon Mine

About Applied Minerals

Applied Minerals is the leading producer of Halloysite Clay solutions from its wholly-owned Dragon Mine property in Utah. Halloysite is aluminosilicate clay that forms naturally occurring nanotubes. In addition to serving the traditional halloysite markets for use in technical ceramics and catalytic applications, the Company has developed niche applications that benefit from the tubular morphology of its halloysite. These applications include carriers of active ingredients in paints, coatings and building materials, environmental remediation, agricultural applications and high-performance additives & fillers for plastic composites.

Applied Minerals' wholly-owned Dragon Mine also contains a high-grade iron oxide resource consisting of Goethite and Hematite. Combining ultra-high purity and consistent quality, the inherent properties of iron oxide from the Dragon Mine allow for a wide range of end uses in pigment and technical applications. Additional information on the company can be found on our company website at www.appliedminerals.com.

About OPF Enterprises

OPF Enterprises, LLC (“OPF”) is a leading advanced ceramic formulation and manufacturing consulting firm specializing in product formulation, manufacturing process design and implementation, plant construction and business development. OPF’s management has over 60 years in the manufacturing world including plant management, site selection, start-ups, team formation, engineering, and process design. OPF has operations in Missoula, MT and Houston, TX. Additional information can be found at www.ontheplantfloor.com.

Safe harbor statements under the Private Securities Litigation Reform Act of 1995 for Applied Minerals, Inc.: Some statements contained or implied in this news release may be considered forward-looking statements, which by their nature are uncertain. Consequently, actual results could materially differ. For more detailed information concerning how risks and uncertainties could affect the Company's financial results, please refer to Applied Minerals’ most recent filings with the SEC. The Company assumes no obligation to update any forward-looking information.