Advantages:

- High porosity

- Fine particle size

- Superb dispersion

- High surface area

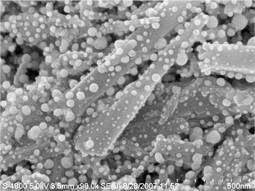

Silver nanoparticles synthesized on Dragonite

Silver nanoparticles synthesized on Dragonite

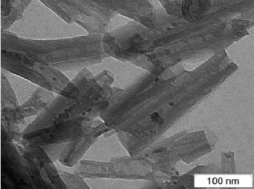

TEM image of Dragonite loaded with Ammonium Molybdate

TEM image of Dragonite loaded with Ammonium Molybdate

Applied Mineral Inc works actively with customers to develop new and innovative solutions for the catalyst industry.

MOLECULAR SIEVES

Dragonite™ lends itself as an excellent binder to zeolite crystals to enhance a molecular sieve’s productivity in critical functions such as drying of natural gas and air, separation of liquid from product streams, and separation of impurities from a gas stream. Dragonite possesses a superb dispersion ability that allows it to combine with the zeolite crystals without attracting to them or reducing the rate of diffusion of liquids and gases. Dragonite’s fine particle size, porosity, and thermal stability also ensure that adsorbates diffuse rapidly through the sieve without affecting the adsorbent blend’s physical properties.

HYDROCRACKING CATALYSTS AND SUPPORTS

Dragonite™ is proven to be an effective catalyst and catalyst support for the hydrotreatment and hydrodemetalation of hydrocarbonaceous feedstocks. Its unique tubular morphology, appropriate pore size, thermal stability, and high surface area combine to create a perfect recipe for removing impurities such as metals, sulfur, nitrogen, and asphaltenes. Halloysite from the Dragon Mine was previously dedicated strictly to this application, successfully supplying the market over 1.1 million tons of material. Applied Minerals can guarantee Dragonite product with the required low levels of iron.