The 267-acre Dragon Mine, located in the Tintic Mining District of Utah, is one of, if not the, largest measured resources of halloysite clay in the western hemisphere. The Dragon Mine also contains a relatively large resource of natrual iron oxcide. Signifcant capital has been spent to characterize the property to enable the Company to supply commercial quantities of halloysite clay and iron oxide to customers operating in an array of industries.

Underground Resource

Halloysite and Other Clays

The Company's past drilling program, targeted over 25-acre area, identified a measured resource of approximately 2,000,000 tons of clay material, of which approximately 500,000 tons are high-grade halloysiye clay.

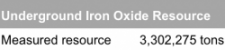

Iron Oxide

The Company's past drilling program also identified a measured resource of approximately 3,300,000 tons of high-purity natural iron oxide.

Further exploration of the 267-acre Dragon Mine is possible.

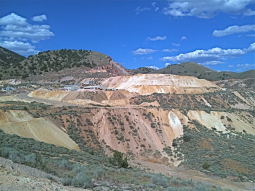

5 Surface Piles

Surface pile on the Dragon Mine property

Surface pile on the Dragon Mine property

The Company, through its geologic survey, has measured five surface piles on the Dragon property encompassing 4.5 million tons of material which can be processed to create purified Halloysite products. The piles were formed by prior operators (from 1949 to 1976) who rejected the mined clay because it did not meet the criteria for their specific end market.

The operators abandoned the Dragon Mine in 1976 when they believed all economic and acceptable resources of Halloysite had been exhausted and an ability to purify the surface piles did not exist (now available today). The surface piles were never removed as the operator failed to appropriately remediate the land. Applied Minerals extraction of material from these surface piles provides that overdue remediation, restoring the land to its natural, undisturbed state.

To date, Applied Minerals has characterized the chemistry and mineralogy of the surface piles and developed a processing system to convert them into purified Halloysite products.

Production Capabilities

Applied Minerals utilizes a dry beneficiation method to process its Halloysite products through a micronizing system located on the mine site. The process utilizes a low energy jet mill without the employment of any chemicals.

Additional capability through 3rd party partnerships

- Wet processing

- Masterbatch production