Home > News Archive > Applied Minerals Inc. Introduces Dragonite™ to the Polymer Composite Market Company Files Provisional Patent Application with the USPTO

- March 01, 2010

- Applied Minerals Inc. Introduces Dragonite™ to the Polymer Composite Market Company Files Provisional Patent Application with the USPTO

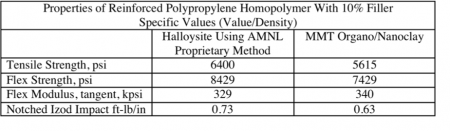

Business Wire NEW YORK -- March 01, 2010 Applied Minerals Inc. (OTCBB:AMNL), a leading global producer of Halloysite Clay, is pleased to announce that it has completed trials incorporating its Halloysite Clay as a drop-in additive for reinforcement in polymer composites. As a result of these trials, the Company has filed a Provisional Patent Application with the USPTO for a novel method of producing a halloysite-polymer composition that (i) eliminates two costly steps typically used in the compounding process and (ii) produces improved properties to other polymer composites reinforced with (a) Halloysite Nanotubes utilizing other composition methods, (b) chemically treated MMT Organo/Nanoclay and (c) certain traditional fillers. Examples of these property improvements are identified in the table below.

Applied Minerals intends to market its line of Halloysite products under the Company’s Dragonite™ brand name. The Dragonite™ line will consist of different grades of Halloysite Clay products tailored to enhance the property performance of each target application, in a cost competitive manner.

The Dragonite^TM group of products is led by its first offering, Dragonite-XR™, a drop-in additive specifically engineered for polymer reinforcement. Composites formed with Dragonite-XR™ exhibit not only high stiffness but also high tensile and flex strength, all with a low density and retained toughness. The Company is currently exploring joint development opportunities with compounders interested in producing a line of polymer composites incorporating Dragonite-XR™.

According to Andre Zeitoun, CEO of Applied Minerals, Inc.: “We believe that our Dragonite XR™ Halloysite Clay product, combined with our patent pending method of compounding, provides the polymer composite industry a large-volume production of high-performance, eco-friendly material with a cost-performance ratio that enables the manufacturer to compete favorably with traditional fillers. In addition to the polymer industry, we are making great progress with our product development engineers demonstrating the benefits of Dragonite™ products for various targeted end market applications. We anticipate launching new product datasheets in the near future.”

Advantages of Dragonite XR™ in Composites

- Lower density than conventional fillers results in reduced weight of finished products.

- Naturally exfoliated morphology provides ease of dispersion at loadings up to 40% without a need for organo-treatment. This results in lower raw material, mixing, and quality control costs compared to organo clays.

- Increases both the stiffness (modulus) and strength of composite with minimal changes in impact strength, weld line strength, and viscosity.

- Improves fatigue resistance and drop impact resistance compared to chopped glass fibers.

- Acts as a nucleating agent with 8°C increase in crystallization temperature, even at 1-3 wt% level, resulting in faster cooling and cycle time.

- Improves thermal stability: 20°C increase in the decomposition temperature in TGA.

- Increases time to ignite, reduces peak heat release rate, and improves char density when added at 5-10 wt% with other conventional flame retardants.

- Lower shrinkage than organo clay and lower warpage than chopped glass fiber and mica. * Increases stiffness and toughness of thermoset compounds.

- Tubular morphology enables the entrapment of active agents followed by their controlled release at predetermined rates.

- Halloysite is an inorganic material that is non-toxic and biodegradable.

- Lower cost than organo clay.

A detailed marketing brochure for Dragonite-XR™ is available to interested parties on the Company’s recently launched website www.appliedminerals.com.

About Applied Minerals Inc. Applied Minerals Inc. is a leading global producer of Halloysite clay from their wholly owned Dragon Mine Property in Utah. Halloysite is aluminosilicate clay that forms naturally occurring nanotubes. In addition to serving the traditional halloysite markets for use in technical ceramics and catalytic applications, the company has targeted niche applications that they feel will benefit from the tubular morphology of their Halloysite. These include: carriers of active ingredients in paints, coatings and building materials, agricultural applications and high-performance fillers in plastic composites.

Statements in this press release that are not historical facts, and this includes all the statements concerning future-oriented statements relating to processing, capacity, costs, notifications, working together, are “forward-looking statements” within the meaning of the Private Securities Litigation Reform Act of 1995, and involve a number of significant risks and uncertainties that could cause actual results to differ materially from those projected, anticipated, expected or implied.